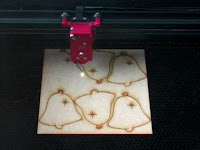

During my product design course in year 12, we did a series of mini projects. One of the projects was to create a clock for a subject area in the school. When it came to choosing materials for our final prototype, I decided to use Acrylic (polymethyl methacrylate). When it came to producing the body of the clock we had major problems making them look right. My school didn't have a very wide range of machinery to use in order to get a good finish on our clock bodies. One student that was on consortium from another school highlighted that their school owned a Laser Cutter. Immediately we jumped at the opportunity of using the software and equipment in order to make our clocks look professional.

The laser cutter works by using x and y co ordinates and a high powered laser which the strength can be altered depening on the thinkness and type of materials being used. I had no idea such technology existed in schools until I saw this one. The design of the clock was produced on Techsoft 2D so that the colours of the outline could be changed. This would allow the laser cutter to identify which lines it needs to cut. I found the laser cutter surprisingly easy to use and was fascinated by how it worked. It took no time at all for it to cut out my clock and it did this with amazing precision and gave a really good overall finish. The amount of time me and the rest of my group spent trying to cut our clocks out using hand tools and band saws was ridiculous. This piece of technology really did make our lives a lot easier.

During my product design course in year 12, we did a series of mini projects. One of the projects was to create a clock for a subject area in the school. When it came to choosing materials for our final prototype, I decided to use Acrylic (polymethyl methacrylate). When it came to producing the body of the clock we had major problems making them look right. My school didn't have a very wide range of machinery to use in order to get a good finish on our clock bodies. One student that was on consortium from another school highlighted that their school owned a Laser Cutter. Immediately we jumped at the opportunity of using the software and equipment in order to make our clocks look professional.

During my product design course in year 12, we did a series of mini projects. One of the projects was to create a clock for a subject area in the school. When it came to choosing materials for our final prototype, I decided to use Acrylic (polymethyl methacrylate). When it came to producing the body of the clock we had major problems making them look right. My school didn't have a very wide range of machinery to use in order to get a good finish on our clock bodies. One student that was on consortium from another school highlighted that their school owned a Laser Cutter. Immediately we jumped at the opportunity of using the software and equipment in order to make our clocks look professional.  The laser cutter works by using x and y co ordinates and a high powered laser which the strength can be altered depening on the thinkness and type of materials being used. I had no idea such technology existed in schools until I saw this one. The design of the clock was produced on Techsoft 2D so that the colours of the outline could be changed. This would allow the laser cutter to identify which lines it needs to cut. I found the laser cutter surprisingly easy to use and was fascinated by how it worked. It took no time at all for it to cut out my clock and it did this with amazing precision and gave a really good overall finish. The amount of time me and the rest of my group spent trying to cut our clocks out using hand tools and band saws was ridiculous. This piece of technology really did make our lives a lot easier.

The laser cutter works by using x and y co ordinates and a high powered laser which the strength can be altered depening on the thinkness and type of materials being used. I had no idea such technology existed in schools until I saw this one. The design of the clock was produced on Techsoft 2D so that the colours of the outline could be changed. This would allow the laser cutter to identify which lines it needs to cut. I found the laser cutter surprisingly easy to use and was fascinated by how it worked. It took no time at all for it to cut out my clock and it did this with amazing precision and gave a really good overall finish. The amount of time me and the rest of my group spent trying to cut our clocks out using hand tools and band saws was ridiculous. This piece of technology really did make our lives a lot easier.

No comments:

Post a Comment